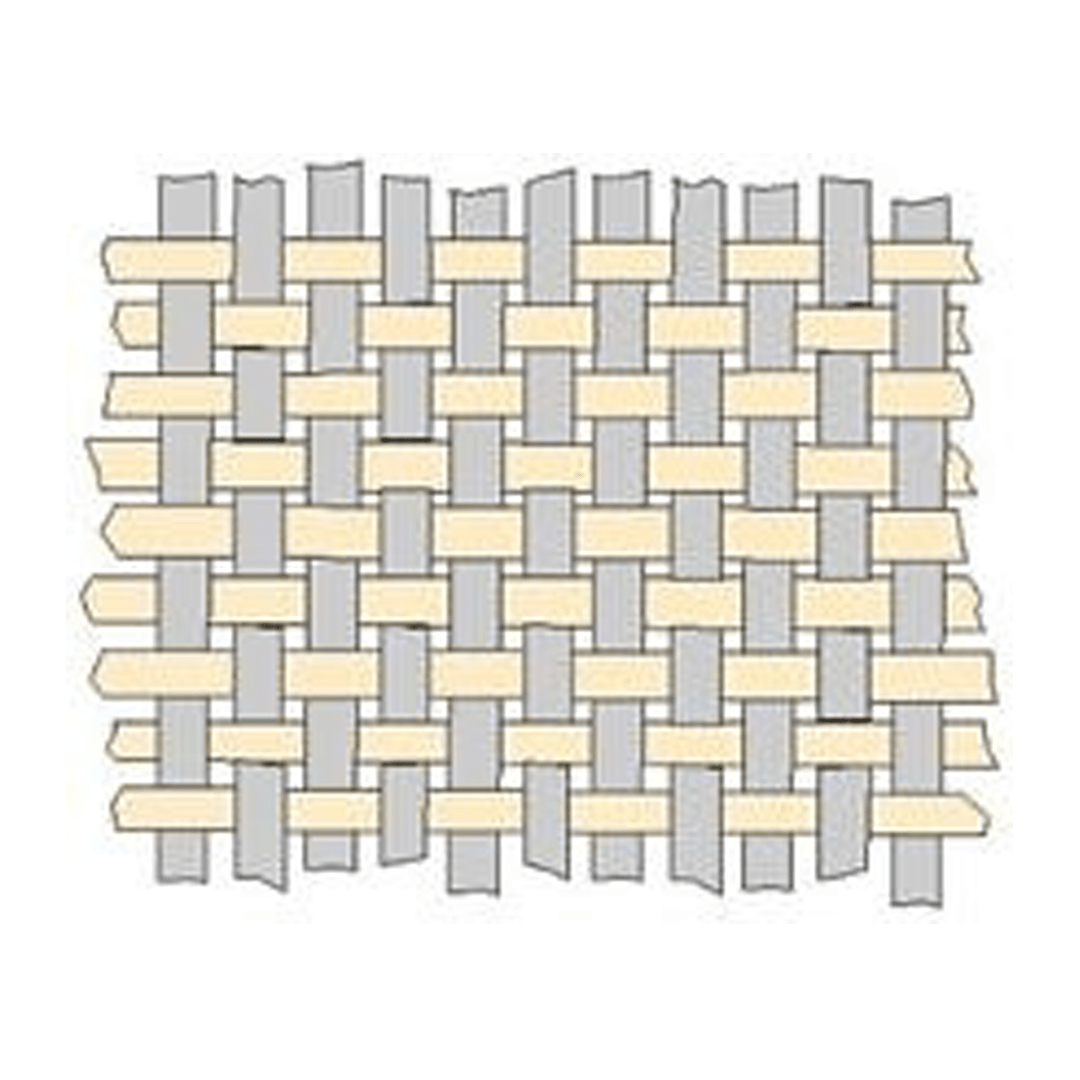

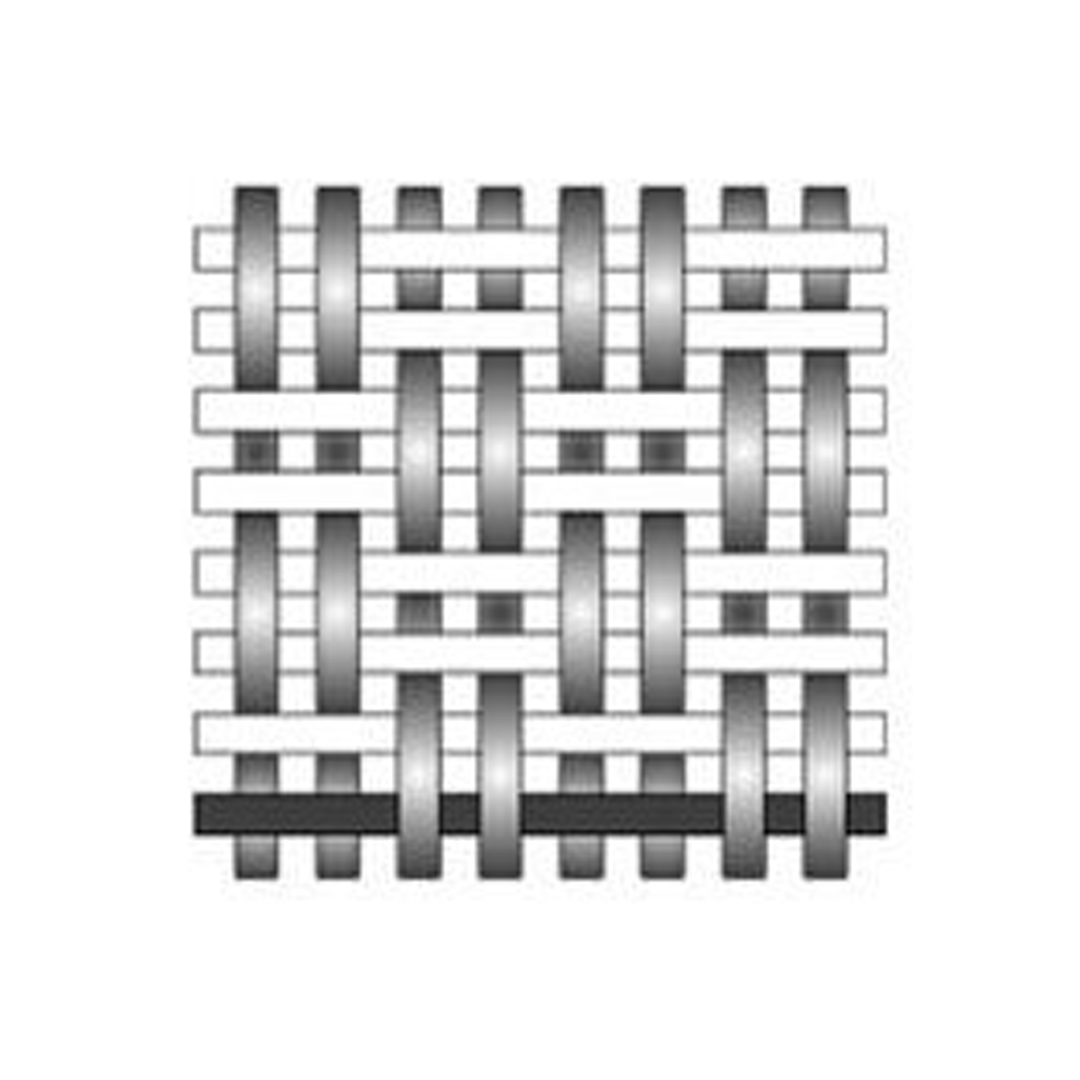

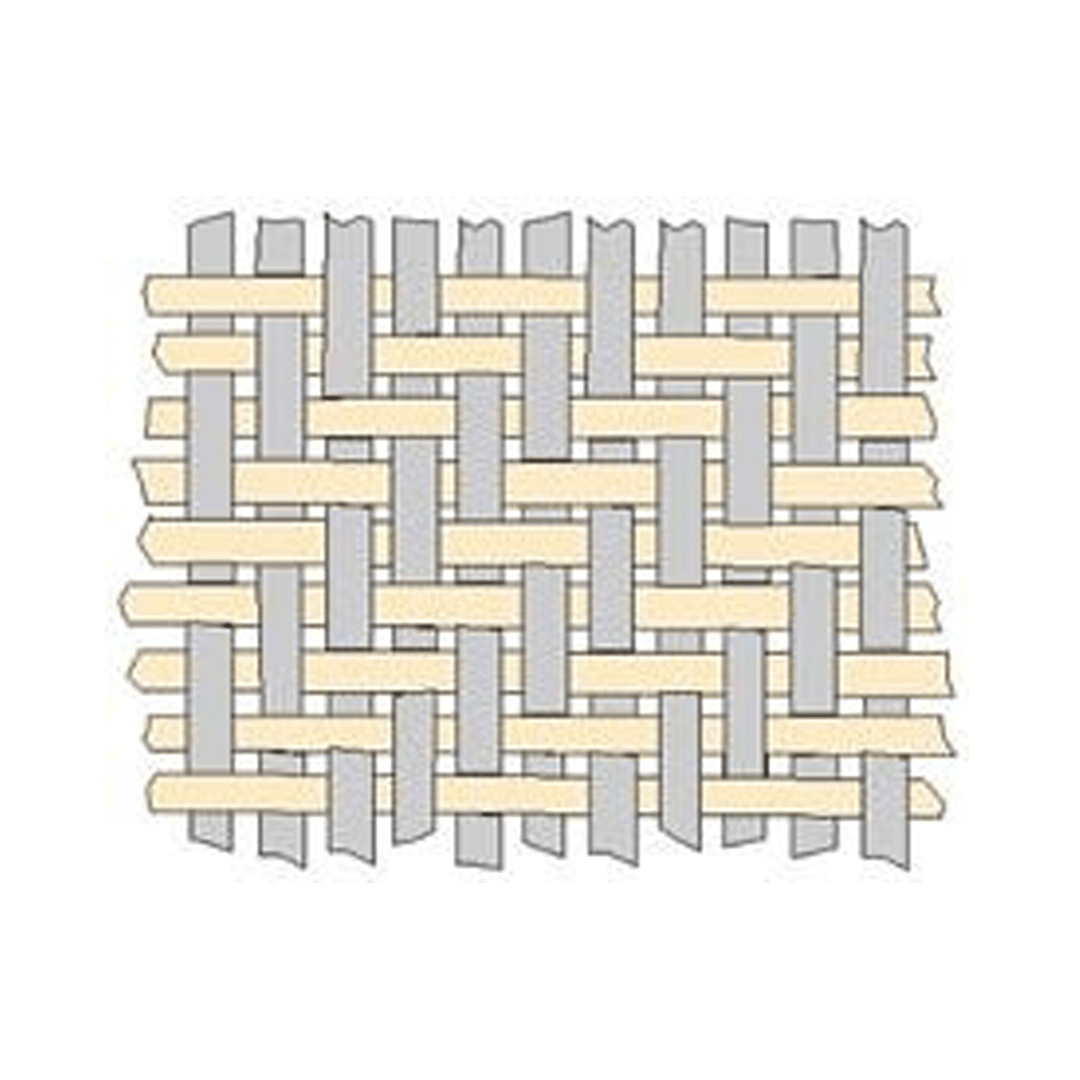

Drawing on a unique carbon fabric processing technology, AvCarb’s carbon fabrics are designed to meet the demanding requirements of gas transport, motion control, electrical and elevated temperature applications.

Fabrics are first carbonized in AvCarb's proprietary continuous carbonization process. After carbonization the fabrics have a carbon content of 88% - 95% and are called “HC” grade fabrics. These ``HC`` grade fabrics are then baked under Vacuum to produce our ``HCB`` grade fabrics which are 99+% carbon and exhibit some graphitic properties.

Produced in long, continuous rolls, AvCarb® carbon fabrics are easy to store, handle and use. Their uniform properties over the length and width of each roll, and from roll to roll, not only assure product consistency but also lend themselves to easy integration with continuous manufacturing processes.